Bicycles/Maintenance and Repair/Headsets/Headset Overhaul

Appearance

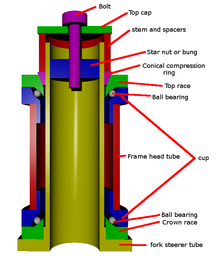

Overview

[edit | edit source]Like most other bicycle bearings the headset needs periodic maintenance to keep it running smoothly.

There are two basic types of headset:

- The style more common on older bikes is the threaded system, so called because the steerer tube of the fork is threaded. The top bearing race (cone) screws onto the fork steerer tube and is held in adjustment by a lock nut. The stem has an extension that extends down into the steerer tube and is held in place by a wedge.

- Most new bikes now use the threadless system. The fork steerer has no threads. Unlike the threaded system the steerer tube extends beyond the top of the headset. The stem clamps onto the steerer tube holding everything together. The headset bearings are tensioned (adjusted) by an allen bolt that pulls up on a star nut inserted into the steerer tube. This applies tension to the upper bearing race. (Loosen the stem to make this adjustment.)

Headsets also use several different bearings types including loose ball bearings, roller bearings and cartridge bearings.

Threadless Headsets

[edit | edit source]

Tools required

[edit | edit source]Disassembly

[edit | edit source]- Remove the pre load adjustment bolt on the top of the steerer tube. Also remove the top cap and any spacers that are above the stem.

- Making sure the fork is supported loosen the bolts clamping the stem to the steerer tube. Now the stem is loose pull it off the steerer tube. Since the stem is holding everything together the fork is free to fall out the bottom of the head tube if not restrained.

- Occasionally the conical compression ring will have a tight grip on the steerer. A gentle tap on the steerer tube with a mallet or your palm will free it up. Some (sealed-bearing) headsets will have a rubber O-ring fitted into the compression ring (bearing cap). Have a replacement handy, or take care not to shear the O-ring.

- Remove the fork from the frame, take care to note the location and orientation of the individual pieces.

- Clean and inspect bearings and races.

Assembly

[edit | edit source]- Apply grease to both cups, crown race and bearings.

- Assemble the parts in reverse order that you removed them

- Slide the stem and spacers onto the steerer tube (but leave loose) and refit the top cap and bolt.

- The bearings are adjusted by tightening and loosening the top bolt. The bearings should be adjusted so there is no play. Clamp the front brake and rock the bike backwards and forwards to check.

- Now the bearings are correctly adjusted line up the stem and tighten the bolts.

Threaded Headsets

[edit | edit source]

Assembly and adjustment

[edit | edit source]Adjustment of the threaded headset bearings is similar to the technique used for all cup and cone bearings. The stem is not a part of the headset and should be removed for all of this work. Don't worry about applying too much grease, excess will be squeezed out.

- Clean all old grease and dirt off all balls, races, cones, etc.

- Apply fresh grease to crown race and place clean (preferably new) bearing balls on the crown race, applying more grease as needed. Be careful not to drop any balls. If the balls are in a cage, slide the cage down the steerer tube and place it on the race.

- Slide the fork into the steerer tube of the frame, again being careful not to drop any balls.

- Apply fresh grease to the top cup and place clean (preferably new) bearing balls on the top cup, applying more grease as needed. Be careful not to drop any balls. If the balls are in a cage, carefully place the cage in the top cup.

- Apply a thin layer of grease to the fork steerer tube threads (mainly to ease removal in the future).

- Screw the threaded race down the fork until it is tight enough to prevent any balls from falling out, but still leaving some play, to be adjusted later.

- Slide down any washers on top of the threaded race. The washers are often keyed to fit in a notch in the steerer tube of the fork.

- Screw the headset locknut down the steerer tube and loosely against the threaded race (and washers).

- Finger tighten the threaded race down so that the fork turns easily but has no side-to-side play. If it is too loose, it will be possible to wobble the fork side-to-side. If the bearings are in poor condition, some compromise might be required, where the movement is slightly difficult in some positions and slightly wobbly in others.

- Holding the threaded race with one hand, finger tighten the locknut against the threaded race.

- Use two headset wrenches (or one headset wrench and one large adjustable wrench), tighten the locknut against the threaded race, without moving the threaded race.

- After the locknut has been tightened, the movement of the fork should still be smooth and without wobble. Loosen the locknut and repeat the previous step until this is achieved. If this can't be achieved, possible causes are: worn bearing balls, worn rolling surfaces, incorrect number of balls, bent fork steerer tube.

- Wipe off excess grease and admire the results of your efforts.