Knots/Print version

Introduction

[edit | edit source]A knot is a method for fastening or securing linear material such as rope by tying or interweaving. It may consist of a length of one or more segments of rope, string, webbing, twine, strap or even chain interwoven so as to create in the line the ability to bind to itself or to some other object - the "load".

Usage

[edit | edit source]There are a large variety of knots and each knot has specific properties and suitability for a range of tasks. Some knots are well-adapted to attach to particular objects such as another rope, cleat, ring, or stake. Other knots are made to bind or constrict around an object. Decorative knots usually bind to themselves to produce attractive patterns. Choosing the correct knot for the job at hand is one of the most fundamental aspects of using knots well. However, if memory is limited, three of the most useful knots are the bowline, the sheet bend, and the clove hitch.

Learning

[edit | edit source]The number of books, websites, videos, and other resources available to those interested in learning about knots is a testament to the value they hold for humankind. While some people possess an innate ability to look at a diagram or photo and tie the illustrated knot, for others the initial stages of learning are best accomplished by being shown knot tying methods by a person who already knows them. Knot tying skills are often transmitted by sailors, scouts, climbers, cavers, arborists, rescue professionals, fishermen, and surgeons. After mastering a few basic knots, the diagrams and photos become easier to interpret and use to continue the learning process. As more knots are learned, patterns begin to become evident in their structure and methods of tying. The learning of knots rewards practice and patience.

Applications

[edit | edit source]Knots are essential in many industrial, occupational, recreational, and domestic settings. Even simple activities such as running a load from the hardware store to home can result in disaster if a clumsy twist in a cord passes for a knot. Truckers needing to tie down a load may use a trucker's hitch, gaining mechanical advantage. Knots can save the spelunker from foolishly becoming buried under millions of tons of rock. Whatever the activity, such as sailing on the water or climbing on a cliff-side rock, learning well-tested knots prior to some hazardous activity introduces a critical measure of safety. In addition to safety, appropriate knots can prevent the necessity of cutting lines.

Basic useful knots

[edit | edit source]Some of the most useful everyday knots are the following. Most are both secure and easy to untie:

- For tying a loop in the end of a rope, as around your waist or to secure a ring or grommet: the bowline.

- For tying the ends of two ropes together: the sheet bend works well even with two different ropes. This is just as easy to tie but much more secure than the square knot. If one rope is much thicker than the other, a double sheet bend is better. (Materials such as cables which are not easily tied may sometimes be joined by two interlocking bowlines instead.)

- The fisherman's knot is similar but easier to tie with cold, wet hands.

- For flat material such as (seat)belts, the water knot is best. (However, this is a poor knot for tying ropes.)

- For tying a rope to a pole, the buntline hitch. A slipped variant is useful for quick release. If both ends of the line will be loaded, then the clove hitch will suffice.

- On square posts where the clove hitch is not secure, two half-hitches is good. It can be hard to untie, so the slipped variant may be useful.

- The timber hitch works well on rough surfaces, including square timber, especially under constant strain, but isn't secure if the load jumps around. The Killick hitch is a variant used for hoisting rocks and other odd shapes.

- The rolling hitch is useful when you don't want a rope to slide up on down a pole, or when tying one rope to the middle of another.

- For a clothesline or other line that sags over time, the taut-line hitch can be ratcheted up to take out the slack.

- The trucker's hitch is useful for clinching down a load.

- The sheep shank is useful for taking slack out of the middle of a rope, but will only hold as long as there's strain on the rope.

- The constrictor knot works well for making bundles or tying the neck of a sack. However, it is nearly impossible to untie once tightened, and will likely need to be cut with a knife.

- The alpine butterfly puts a secure loop in the middle of a rope when the ends aren't free.

- For climbing a rope, the Prusik knot allows you to make footholds out of loops of narrower rope which ratchet up the main rope. (The loop can be made by tying together the ends of a rope with a double fisherman's knot.)

- The diamond hitch works well for packing trail animals.

- The figure-of-eight knot stops the end of a rope from slipping through a hole or other tight spot.

Rope

[edit | edit source]

A rope is a length of fibres, twisted or braided together to improve strength for pulling and connecting. It has tensile strength but is too flexible to provide compressive strength (it can be used for pulling, but not pushing). Rope is thicker and stronger than similarly constructed cord, line, string, or twine.

Construction

[edit | edit source]Common materials for rope include Natural fibres such as Manila hemp, hemp, linen, cotton, coir, jute, and sisal.

Synthetic fibres include polypropylene, nylon, polyesters (e.g. PET, LCP, HPE, Vectran), polyethylene (e.g. Spectra), aramids (e.g. Twaron, Technora and Kevlar) and polyaramids (eg Dralon, Tiptolon). Some ropes are constructed of mixtures of several fibres or use co-polymer fibres.

Styles of rope construction

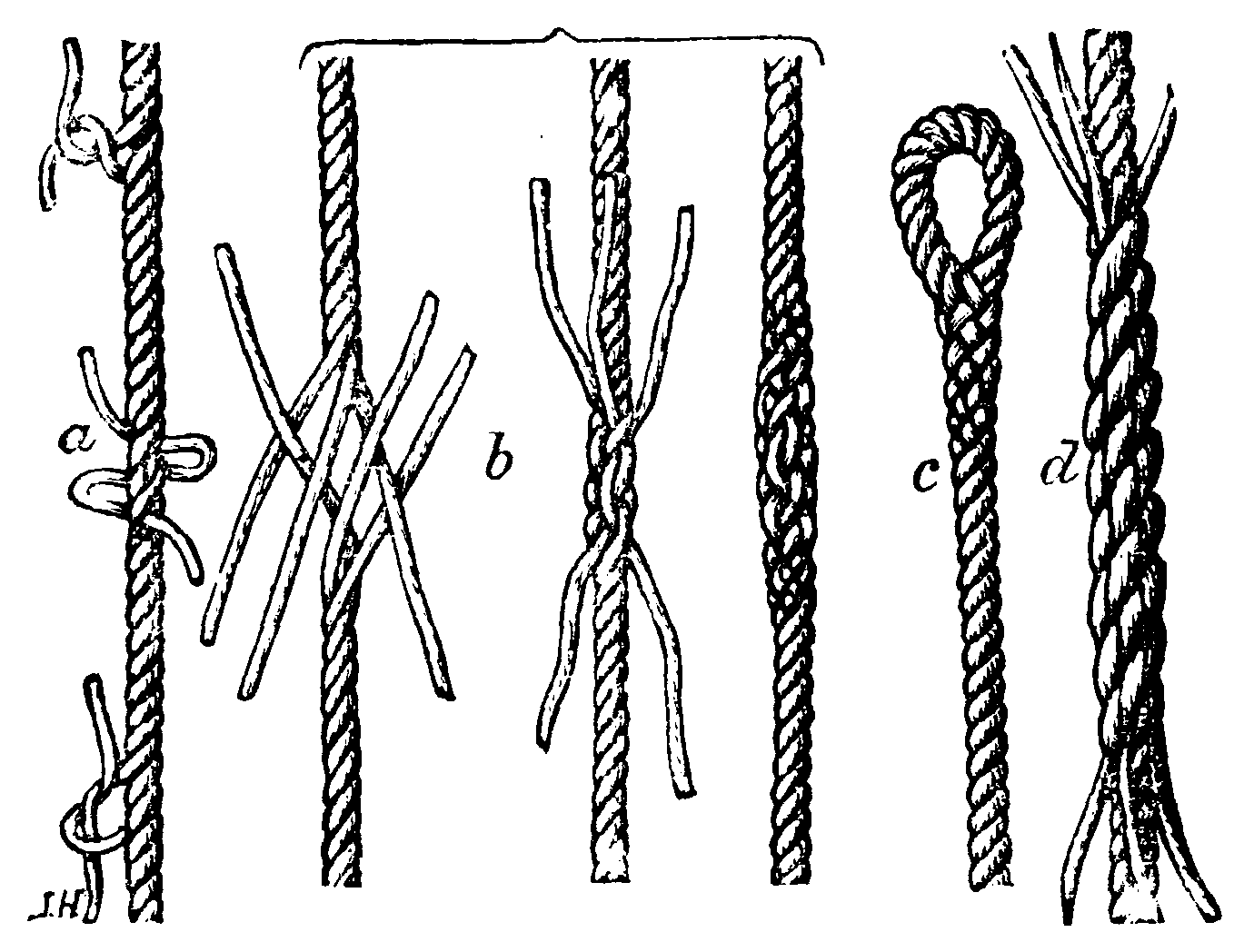

[edit | edit source]Laid or twisted rope

[edit | edit source]Laid rope, also called twisted rope, is historically the prevalent form of rope, at least in modern Western history. Most twisted rope consists of three strands and is normally right-laid, or given a right-handed twist. Typically, a three strand laid rope is called a plain or hawser-laid rope. A four strand rope is usually called shroud-laid, and a rope twisted out of 3 or more ropes is called cable-laid.

Twisted ropes are built up in three steps. First, fibers are gathered and spun to form yarns. A number of these yarns are then twisted together to form strands. The strands are then twisted together to form the rope. The twist of the yarn is opposite to that of the strand, and that in turn is opposite to that of the rope. This counter-twisting helps keep the rope together. On the other hand, rope constructed in this manner untwists under tension, which is the cause of spinning, kinking, hockling and stretching. Any rope of this type must be bound at its end by some means to prevent untwisting. Twisted ropes have a preferred direction for coiling. Normal right laid rope should be coiled with the sun, or clockwise, to prevent kinking. Coiling this way imparts a twist to the rope. One of the drawbacks of this construction is that every fiber is exposed to abrasion numerous times along the length of the rope. This means that the rope can degrade to numerous inch-long fiber fragments, which is not easily detected visually.

Braided rope

[edit | edit source]

Braided ropes are generally made from nylon, polyester or polypropylene. Nylon is chosen for its elastic stretch properties and good resistance to ultraviolet light. Polyester is about 90% as strong as nylon but stretches less under load, is more abrasion resistant, has better UV resistance, and has less change in length when wet. Polypropylene is preferred for low cost and light weight (it floats on water).

Single braid consists of even number of strands, eight or twelve being typical, braided into a circular pattern with half of the strands going clockwise and the other half going anticlockwise. The strands can interlock with either twill or plain weave. The central void may large or small; in the former case the term hollow braid is sometimes preferred. Double braid, also called braid on braid, consists of an inner braid filling the central void in an outer braid, that may be of the same or different material. Often the inner braid fiber is chosen for strength while the outer braid fiber is chosen for abrasion resistance. In solid braid the strands all travel the same direction, clockwise or anticlockwise, and alternate between forming the outside of the rope and the interior of the rope. This construction is popular for general purpose utility rope but rare in specialized high performance line.

Kernmantle rope has a core (kern) of long twisted fibers in the center, with a braided outer sheath or mantle of woven fibers. The kern provides most of the strength (about 70%), while the mantle protects the kern and determines the handling properties of the rope (how easy it is to hold, to tie knots in, and so on). In dynamic climbing line, the core fibers are usually twisted, and chopped into shorter lengths which makes the rope more stretchy. Static kernmantle ropes are made with untwisted core fibers and tighter braid, which causes them to be stiffer in addition to limiting the stretch.

Braided ropes (and objects like garden hoses, fiber optic or coaxial cables, etc.) that have no lay, or inherent twist, will uncoil better if coiled into figure-8 coils, where the twist reverses regularly and essentially cancels out.

Other types

[edit | edit source]Plaited rope is made by braiding twisted strands, and is also called square braid. It is not as round as twisted rope and coarser to the touch. It is less prone to kinking than twisted rope and, depending on the material, very flexible and therefore easy to handle and knot. This construction exposes all fibers as well, with the same drawbacks as described above. Brait rope is a combination of braided and plaited, a non-rotating alternative to laid three-strand ropes. Due to its excellent energy-absorption characteristics, it is often used by arborists. It is also the most popular rope for anchoring and can be used as mooring warps. This type of construction was pioneered by Yale Cordage.

Handling rope

[edit | edit source]

Rope made from hemp, cotton or nylon is generally stored in a cool dry place for proper storage. To prevent kinking it is usually coiled. To prevent fraying or unraveling, the ends of a rope are bound with twine, tape, or heat shrink tubing. The ends of plastic fiber ropes are often melted and fused solid.

If a load-bearing rope gets a sharp or sudden jolt or the rope shows signs of deteriorating, it is recommended that the rope be replaced immediately and should be discarded or only used for non-load-bearing tasks.

Line

[edit | edit source]A piece of rope that has a specific purpose is called a line, especially in nautical usage. Examples include clothesline, chalk line, anchor line, stern line, fishing line, and so on.

Synthetic fibre

[edit | edit source]Synthetic fibres include polypropylene, nylon, polyesters (e.g. PET, LCP, HPE, Vectran), polyethylene (e.g. Spectra), aramids (e.g. Twaron, Technora and Kevlar) and polyaramids (eg Dralon, Tiptolon). Some ropes are constructed of mixtures of several fibres or use co-polymer fibres.

Here, we will talk about the generic kinds of synthetic cordage — if you require specific information on a particular fiber, you should consult the spec sheet available from the retailer.

Strength

[edit | edit source]Synthetic fibres are stronger than natural fibres, so they are preferred for high-performance applications such as climbing. As well, they are resistant to rot and mildew, and aren't edible so rodents will not eat the cordage.

Water

[edit | edit source]Nylon loses about 15% of its strength when wet, which is recovered again when dry. Polyester is slightly weaker than nylon, but retains its strength whether wet or dry. Polypropylene degrades when exposed to UV radiation, unless specifically treated.

Elasticity

[edit | edit source]Nylon stretches, which means it will absorb some of the energy of sudden loading — this means there is a lesser risk of breakage from suddenly overloading. This makes it suitable as a tow rope, certain climbing ropes (though not all), for mooring boats, and fishing lines. These applications require cordage which can withstand shock-loading. Nylon returns to its original length after unloaded.

Polyester is not elastic — what little elasticity it has is removed during the manufacturing process. This makes it ideal for applications where shock-loading is unlikely and stretch is undesirable. One such application is on sailboats: the shrouds, stays, and other standard vertical rigging as well as halyards, sheets and other running rigging through blocks, tackles or purchases.

Polypropylene is weaker still, but is very cheap, and floats. This makes it ideal for non-technical applications such as rescue lines and ski tow lines.

Specialty synthetics

[edit | edit source]- Kevlar, Twaron and Technora

- These are aramid derivatives

- Spectra and Dyneema

- HMPE or high modulus polyethylene (UV-stable)

- Vectran

- LCP or poly(p-phenylene-3,6 benzobisoxazole)

These synthetics are quite expensive, but have higher tensile strength than steel. Some have poor resistance to abrasion, low flex fatigue or are UV-unstable. However, when you buy cordage, they will normally have a polyester sheath which protects the inner cordage. These types of cordage are suitable for technical applications — check the specs for further information.

Webbing

[edit | edit source]Webbing is a fabric woven as a flat strip or tube of varying width and fibers often used in place of rope. The name webbing comes from the meshed material frequently used in its construction, which resembles a web. It is a versatile component used in climbing, slacklining, furniture manufacturing, automobile safety, auto racing, towing, parachuting, military apparel, and many other fields. Modern webbing is often made from exceptionally high-strength material, such as Dyneema, Nylon, Polyester, and Kevlar. Webbing is both light and strong, with breaking strengths readily available in excess of 10,000 lb (44.4 kN)

Sporting goods

[edit | edit source]In rock climbing, nylon webbing is used in slings, runners, harnesses, anchor extensions, etriers (ladders) and quickdraws.

The most popular webbing is one inch but it is available in two and three inch widths which in earlier days were often used in lieu of climbing harnesses. Wrapped around the waste several times, they were less bulky and more comfortable than the old school method of tying the rope around the waist. More elaborate configurations would include leg loops, which were essential to hold a climber who had fallen or otherwise found themselves dangling. If left supported only by rope or webbing wrapped around the waist, breathing would be constricted and many climbers died as a result of the lack of support which did not constrict the diaphragm.

Narrower webbing is frequently looped through chockstones which are typically metal in shapes such as hexagonal, square, tubular, T, etc., and which are jammed into cracks as safety anchors. In other cases, webbing is looped over rock outcroppings. Unlike tubular rope, webbing is less likely to inch its way off the rock. Note that webbing construction is either utterly flat or flat-tubular; the latter tends to handle better but knots are more likely to jam.

The most popular knots in webbing are the water knot and the grapevine knot. The latter is stronger, but uses more webbing for the knot. It is customary to leave a couple inches extending from the knot, and in many cases climbers tape the ends down onto the main loops. Webbing is also less expensive than rope of similar size particularly kernmantle rope which requires elaborate and expensive manufacturing. Unlike rope, which has manufacturers seeking brand identification and customer loyalty, webbing manufacture is typically generic. Climbing shops sell it off of a spool on a per yard or per foot basis. It is cut with a hot wire as is nylon rope, which prevents fraying and unravelling. However, when webbing does fray and unravel, the result is less disastrous than with rope, which is another albeit minimal advantage. Webbing suffers the drawback of less elasticity than perlon rope, and it may be more difficult to handle with gloves or mittens on. [1][2][3]

Caring for cordage

[edit | edit source]Cordage is often expensive, and may be difficult to replace. For all cordage, there are some things you can do to maximize its lifespan:

- Protect cordage from rough treatment

- Do not stand on cordage, especially synthetics

- Keep cordage away from chemicals, oil, grease dirt and grit

- Avoid extremes of cold or heat

- Limit exposure to sunlight, even for UV-stable cordage

- Thoroughly wash and rinse your cordage regularly

- Keep natural fibre ropes dry

- Only short lengths of non-production rope should be folded; everything else should be coiled.

- Load-bearing cordage must be inspected regularly

- Look for cut or frayed fibres, wrinkled or ruptured sheath, glazing/fusing from thermal friction

- Even though the sheath is flawless, it may mask internal damage

- Keep a log for load-bearing cordage

- Cordage with a history of hard work, or severe shock-loading should be retired or downgraded

- Base your cordage life cycle on the specifications and the specific applications. Ask your vendor for assistance, if necessary, or get training.

Coiling

[edit | edit source]Properties of knots

[edit | edit source]| This page was transwikied from another project and needs to be bookified. This page either needs to be altered to become the main page of a book, or altered to fit the "local manual of style" of the book it is to be included in. Please remove {{bookify}} after the page is bookified. |

Properties

[edit | edit source]Strength

[edit | edit source]Knots invariably weaken the rope they are made in. When knotted rope is strained to its breaking point, it almost always fails in or near the knot, unless it is defective or damaged elsewhere. The bending, crushing, and chafing forces that hold a knot in place also unevenly stress the rope fibers and ultimately lead to the reduction of strength. The exact mechanisms that cause the weakening and failure are complex and are the subject of continued study.

The relative knot strength, also called knot efficiency, is the breaking strength of a knotted rope as a proportion of the breaking strength of the rope without the knot. There are many difficulties in determining an overall numeric knot efficiency for a given knot. This is due to the many factors that can affect the results of a knot efficiency test: the type of fiber, the style of rope, the size of rope, whether it is wet or dry, how the knot is dressed before loading, how rapidly the knot is loaded, whether the knot is repeatedly loaded, and so on. With those limitations noted, most common knots have an efficiency between 40% and 80%.

While some rope splices can retain nearly the full strength of the rope when forming loops and bends, conventional knots are much more practical in most situations. Thus the prudent knot user will always allow for a large safety margin in the strength of rope chosen for a task due to the weakening effects of knots, ageing, damage, shock loading, etc. In general, the safe working load is often specified as between 10% and 20% of the rated breaking strength of the rope being used.[1] For safety of life applications many other factors come into play which are beyond the current scope of this article. Experienced practitioners should always be consulted before using ropes and knots when safety of life, limb, or property is involved.

Security

[edit | edit source]Even if the rope does not break, a knot may still fail to hold. A knot which holds firm under a variety of adverse conditions is said to be more secure than one that does not. The main ways knots fail to hold are:

Slipping

[edit | edit source]The tension from the load causes the rope to work back through the knot in the direction of the load. If this continues far enough, the working end will pass into the knot and the knot unravels and fails. This behavior can be worsened when the knot is repeatedly strained and let slack, dragged over rough terrain, or repeatedly impacted such as against a mast or flagpole.

Even with secure knots, some slippage may occur as the knot is first put under real tension. This can be dealt with by leaving plenty of rope at the working end outside of the knot and by dressing the knot cleanly and tightening it as fully as possible before loading. In some cases the use of a stopper knot or, even better, a backup knot can prevent the working end from passing through the knot, but it is generally better to use a more secure knot if one is observed to slip. In life critical uses backup knots are often added to already secure knots in order to maximize safety.

Capsizing

[edit | edit source]

Capsizing (or spilling) a knot is changing its form, rearranging its parts, usually by pulling on specific ends in specific ways. Some knots when used in an inappropriate way tend to capsize easily or even spontaneously. Often the capsized form of the knot offers little resistance to slipping or unraveling. For an excellent example of a knot that capsizes dangerously, see the discussion of the reef knot used as a bend.

Sometimes a knot is intentionally capsized as a method of tying another knot, such as the "lightning method" of tying a Bowline. Some knots, such as the Carrick Bend, are generally tied in one form and then capsized to attain a stronger or more stable form.

Sliding

[edit | edit source]In knots that are meant to grip another object, failure can be defined as the knot moving relative to the object being gripped. While the knot itself does not fail, it ceases to perform the desired function. For example a simple Rolling Hitch tied around a railing and pulled parallel to the railing might hold to a certain tension and then start sliding. Sometimes this can be corrected by working-up the knot tighter before subjecting it to load but usually a knot with more wraps, or a different size or type of rope will need to be used.

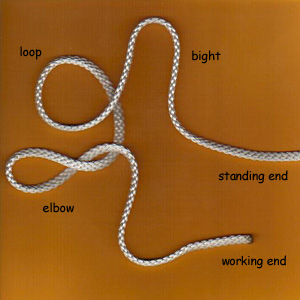

Components

[edit | edit source]Components

[edit | edit source]

B: Round turn

C: Two round turns

- Bight

- The center part of a length of rope, string, or yarn as opposed to the ends.

- A "bight" is any curved section, slack part, or loop between the ends of a rope.

- The phrase "in the bight" implies a U-shaped section of rope is itself being used in making a knot. Many knots can be tied either with the end or in the bight.

- Bitter end

- This is a commonly misused term, meaning the end of the line at the bitts. A bitt is a metal block with a crosspin used for tying lines to, found on docks.

- Loop

- A full circle formed by passing the working end over itself. Note that the term 'loop' is also used to refer to a category of knots (see 'Categories' below).

- Elbow

- Two crossing points created by an extra twist in a loop.

- Standing end

- The end of the rope not involved in making the knot, often shown as unfinished.

- Standing part

- Section of line between knot and the standing end.

- Turn

-

- A turn or single turn is a single pass behind or through an object.

- A round turn is the complete encirclement of an object; requires two passes.

- Two round turns circles the object twice; requires three passes.

- Working end

- The active end of a line used in making the knot. May also be called the 'running end'.

- Working part

- Section of line between knot and the working end.

Bowline

[edit | edit source]

The bowline (bow-linn) is an ancient but simple knot used to form a fixed loop at the end of a rope. The structure of the bowline is identical to that of the sheet bend, except the bowline forms a loop in one rope and the sheet bend joins two ropes. Along with the sheet bend and the clove hitch, is often considered one of the most essential knots.

The name has an earlier meaning, dating to the age of sail. On a square-rigged ship, a bowline (sometimes spelled as two words, bow line) is a rope that holds the edge of a square sail towards the bow of the ship and into the wind, preventing it from being taken aback. A ship is said to be on a "taut bowline" when these lines are made as taut as possible in order to sail close-hauled to the wind.

Usage

[edit | edit source]

The bowline is used mainly to make a temporary loop at the end of a line. Like the other similar knots, it can be made and then secured over an object like a post. Since the bowline is generally tied with the working end, it can be passed through a ring or other object before the knot is tied. This feature makes the bowline a convenient and useful loop knot.

The bowline, or more commonly one of its variations such as the double bowline, is sometimes used by climbers to tie the end of the rope to a climbing harness, or the like. The advantage of the bowline in this application is that the knot is easy to untie even after it has been loaded. The disadvantage is that, while it is a very strong knot under load, it has a tendency to loosen up and become untied when it is unloaded and shaken around over a period of time, as might happen during a climb. Several other knots are more commonly used in modern climbing technique.

This knot can be used in an emergency to hoist a person to safety, since the loop can slipped over a victim's torso, under the armpits, and it will not tighten around the victim's chest and prevent breathing. This is useful when a rescue harness is not available.

The bowline is commonly used in sailing small craft, for example to fasten a halyard to the head of a sail or to tie a jib sheet to a clew of a jib.

A rope with a bowline retains about 65% of its strength at the location of the knot.

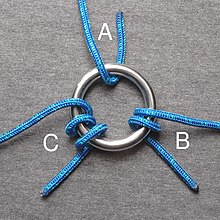

Tying

[edit | edit source]A mnemonic used to teach the tying of the bowline is to imagine the end of the rope as a rabbit, and where the knot will begin on the standing part, a tree trunk. First a loop is made near the end of the rope, which will act as the rabbit's hole. Then the "rabbit" comes up the hole, around and under the tree, and then back down the hole. When this configuration is tightened, a bowline has been tied. An alternative "lightning method" can also be used.

-

The rabbit hole. (Take note of which end is over which.)

-

Out comes the rabbit,

-

runs around the tree,

-

and hops back into its hole.

-

Lightning method, tied on a ring. Pull per the blue arrows.

Related knots

[edit | edit source]Constrictor

[edit | edit source]The Constrictor knot is one of the most effective binding knots. Simple and secure, it is a harsh knot which can be difficult or impossible to untie once tightened. It is made similarly to a clove hitch but with one end passed under the other, forming an overhand knot under a riding turn. The Double constrictor knot is an even more robust variation having two riding turns.

Usage

[edit | edit source]The Constrictor knot is appropriate for situations where secure temporary or semi-permanent binding is needed. Made with small-stuff it is especially effective, as the binding force is concentrated over a smaller area. Tied over soft material, such as the neck of a bag, use hard stiff cord. Tied over a hard surface, use soft stretchy line. The Constrictor knot's severe bite, which makes it so effective, can damage or disfigure items it is tied around. To exert extreme tension on the knot without injuring the hands fashion handles for the ends using Marlinespike hitches made around two rods.

Constrictor knots can be for used for temporarily binding the fibres of a rope or strand end together while splicing or when cutting to length and before properly whipping the ends. Constrictor knots can also be quite effective as improvised hose clamps or cable ties. Noted master-rigger Brion Toss says of the Constrictor, "To know the knot is to constantly find uses for it...."

Tying

[edit | edit source]The method shown below is the most basic way to tie the knot. Other methods exist which can be used to tied it in the hand or over the end of the object to be bound.

- Make a turn around the object and bring the working end back over the standing part.

- Continue around behind the object.

- Pass the working end over the standing part and then under the riding turn and standing part, forming an overhand knot under a riding turn.

- Be sure the ends emerge between the two turns as shown. Pull firmly on the ends to tighten.

Variations

[edit | edit source]Double constrictor knot

[edit | edit source]If a stronger and even more secure knot is required an extra riding turn can be added to the basic knot to form a Double constrictor knot. It is particularly useful when tying the knot with very slippery twine, especially when waxed. Adding more than one extra riding turn does not add to its security and makes the knot more difficult to tighten evenly.

- Make a turn around the object and bring the working end back over the standing part.

- Make a second turn following the same path as the first

- Pass the working end over the standing part, then under both riding turn and standing part, forming an overhand knot under two riding turns.

- Be sure the ends emerge between the turns as shown. The Double constrictor may require more careful dressing to distribute the tension throughout the knot. After working up fairly tight, pull firmly on the ends to finish.

Slipped Constrictor knot

[edit | edit source]This variation is useful if it is known beforehand that the constrictor will need to be released. Depending on the knotting material and how tightly it is cinched, the slipped form can still be very difficult to release.

- Make a turn around the object and bring the working end back over the standing part.

- Continue around behind the object.

- Pass a bight under the standing part and riding turn, instead of using the end itself.

- Be sure the bight and ends emerge between the two turns as shown. To release, tug on the working end so that the bight passes back through the knot.

Releasing

[edit | edit source]

A heavily tightened Constrictor knot will likely jam. If the ends are still long enough, it may be possible to untie by pulling one end generally parallel to the bound object and a bit up away from it, and prying it into the opposite end's part to open the knot. The use of a pick, marlinespike, or some other tool able to be forced between parts can help.

If the ends have been trimmed short, or the knot is otherwise hopelessly jammed, it can be easily released by cutting the riding turn with a sharp knife. The knot will spring apart as soon as the riding turn is cut. If care is taken not to cut too deeply, the underlying wraps will protect the bound object from being marred by the knife.

Security

[edit | edit source]The Constrictor and Double Constrictor are both extremely secure when tied tightly around convex objects with cord scaled for the task at hand. If binding around a not fully convex, or square-edged, object arrange the knot so the overhand knot portion is stretched across a convex portion, or a corner, with the riding turn squarely on top of it. In situations where the object leaves gaps under the knot and there are no corners, it is possible to finish the Constrictor knot off with an additional overhand knot, in the fashion of a Reef knot, to help stabilize it. Those recommendations aside, Constrictor knots do function best on fully convex objects.

If an item, such as a temporarily whipped rope, is going to be cut very close to where a Constrictor binds it a Boa knot may remain more stable.

Figure-eight knot

[edit | edit source]

The figure-eight knot is a simple stopper knot. To tie it, make a loop, then turn the working end around to the other side of the loop and put it through, so that it looks like the picture. It is an overhand knot with an extra turn around the standing part.

Lark's head

[edit | edit source]Reef knot

[edit | edit source]

The square knot aka reef knot is a common and simple binding knot.

Tying a reef knot

[edit | edit source]To tie a reef knot, tie a left-handed overhand knot and then a right-handed overhand knot or vice versa. (Two consecutive overhands of the same handedness will make a granny knot.) A common mnemonic for this procedure is "right over left, left over right", which is often appended with the rhyming suffix "... makes a knot both tidy and tight".

The working ends of the reef knot must be cis (that is, both at the top or both at the bottom); the other lines lead to the full rope. Otherwise, a thief knot results. (The "cis" and "trans" terms are derived from terminology used to describe geometric isomerism.)

Uses

[edit | edit source]Used to tie two ends of a single line together such that they will secure something that is unlikely to move much. It lies flat when tied with cloth, and has been used for bandages for millennia. With both ends tucked (slipped) it becomes a good way to tie shoelaces, whilst the non-slipped version is useful for shoelaces that are excessively short. It is also used decoratively and to tie the Obi (or belt) of a martial arts keikogi. Finally, it is quite handy for tying plastic garbage or trash bags, as the knot forms a handle when tied in two twisted "ears".

This knot's name originates from its use to "reef" sails (tie part down to decrease effective surface area), where its easy-spilling behavior was very handy. A sailor could collapse it with a pull of one hand; the sail's weight would make the collapsed knot come apart.

The reef knot is one of the key knots of macrame textiles.

Misuse

[edit | edit source]

The reef knot's ease of tying and visually appealing symmetry belie its weakness. It is popular as a general-purpose binding knot. In particular, it figures prominently in Scouting worldwide: each Scout is said to know the square knot, and it is pictured in the international membership badge.

The International Guild of Knot Tyers warns that this knot should never be used to [[../../Bend knots|bend]] two ropes together. A proper bend (such as the double fisherman's knot) should be used instead. Some knotting guides claim that misused reef knots cause more deaths and injuries than all other knots combined.[4]

Related knots

[edit | edit source]-

Reef (square) knot

-

Thief knot

-

Granny knot

-

Grief knot

Thief knot

[edit | edit source]The thief knot is an intentional mis-tie of the knot, where the open ends are on opposite sides. It is traditionally used as an inexpensive method of detecting if a sack was opened where the thief would retie a standard reef knot. However, it does not provide as much strength for binding ropes.

Granny knot

[edit | edit source]The granny knot is a common mis-tie of the reef knot by tying both portions of the knot in the same direction. This knot can release suddenly and unpredictably, and should be avoided.

Grief knot

[edit | edit source]The grief knot shares common properties of both the thief knot and the granny knot, and likewise it is a weak knot. It is more of a trick knot, as it is possible to "lock" the knot so that it won't slip; however, locking this knot does not guarantee as much strength as the normal reef knot.

References

[edit | edit source]- Ashley's Book of Knots ISBN 0-385-04025-3

External references

[edit | edit source]- Grog's Animated Knots: How to tie the reef knot

- Ian's Shoelace Site: Reef Knot

- Notable Knot Index

- IGKT Sea Cadet Knots

- The Reef Knot Family

Sheet bend

[edit | edit source]Knots/Print version/Bend knots/Sheet bend

Double sheet bend

[edit | edit source]

The double sheet bend is a variation on the sheet bend. If the ropes that one wishes to join in a bend are of greatly different sizes, it may be necessary make the double sheet bend by putting the smaller one under itself twice (first at the bottom of the bight, second nearer the tip) instead of only once (as in a normal sheet bend).

Two half-hitches

[edit | edit source]Bend knots

[edit | edit source]A bend knot is a knot used to join two lengths of rope.

Although the Reef knot can be used in this way, it is insecure when used as a bend and so is not classed as one.

Bend knots

[edit | edit source]Binding knots

[edit | edit source]A binding knot is a knot that may be used to keep an object or multiple loose objects together, using a string or a rope that passes at least once around them. There are various binding knots, divided into two types.

Friction knots

[edit | edit source]Friction knots are held in place by the friction between the windings of line. Knotted-ends knots are held in place by the two ends of the line being knotted together.

- Constrictor

- Miller's knot

- Packer's knot

- Reef knot (Square knot)

- Surgeon's knot

- Trucker's hitch

- Two half hitches

Whipping and seizing knots

[edit | edit source]Whipping and Seizing serve a similar function to binding knots, but are classified differently since they contain many turns, like a lashing.

Decorative knots

[edit | edit source]Decorative knots (as you may have guessed) are knots that are designed to have aesthetic appeal. They are hard and long, but fun to tie.

Decorative knots

[edit | edit source]Heaving knots

[edit | edit source]Heaving knots make ropes easier to throw.

Hitch knots

[edit | edit source]Hitches are used to tie a rope to something.

Hitch knots

[edit | edit source]- Anchor bend

- Buntline hitch

- Cat's paw

- Clove hitch

- Icicle hitch

- Lark's head (Cow hitch/Girth hitch)

- Pipe hitch

- Prusik hitch

- Round turn

- Taut-line hitch

- Timber hitch

- Two half hitches

Lashing

[edit | edit source]A lashing is an arrangement of rope used to secure two or more items together in a somewhat rigid manner. Lashings are most commonly applied to timber poles, and are commonly associated with the scouting movement and with sailors.

This word usage derives from using whipcord to tie things together.

Technique

[edit | edit source]The structure of a lash is nearly the same with any type of lashing: to start, hold two poles in the desired end position. Start a timber hitch around one of the poles to secure the rope onto the pole (in the case of the stockgrower's lash, an adjustable grip hitch or tautline hitch is used, as a timber hitch can slip when the lash is opened). Start to wrap the rope around the poles (the wrap will change when different lashings are used). Once the rope is wrapped around the poles enough to be very tight, end with two timber hitches and one or two clove hitches.

Types

[edit | edit source]Loop knots

[edit | edit source]The word "loop" has two different senses when used in reference to knots.

- A loop is one of the fundamental structures used to tie knots. Specifically, it is a full circle formed by passing the working end over itself. See knot terminology description image.

- A loop is a knot used to create a closed circle in a line.

Loop knots

[edit | edit source]- Adjustable grip hitch

- Alpine butterfly

- Bowline

- Bowline on a bight

- Figure-eight loop

- French bowline (Portuguese bowline)

- Lariat knot (Bowstring knot/Honda knot)

- Man harness knot

- Taut-line hitch

- Triple bowline

- Triple crown knot

- Water bowline

- Yosemite bowline

Seizing knots

[edit | edit source]Seizing knots

[edit | edit source]Sinnet knots

[edit | edit source]Sinnet (or sennit) knots are knots that involve weaving in a pattern.

- Daisy chain (Chain sinnet)

- Five-string English sinnet

- Three-string English sinnet

Rope splicing

[edit | edit source]

Rope splicing is the forming of a semi-permanent join between two ropes or two parts of the same rope by partly untwisting and then interweaving their strands. Splices can be used to form a stopper at the end of a line, to form a loop or an eye in a rope, or for joining two ropes together. The resulting join is stronger than the equivalent using knots although it usually results in a thickening of the line and if subsequently removed a distortion of the rope. Most types of splices are used on 3 strand rope, but some can be done on 12 or greater strand braided rope.

Types of splices

[edit | edit source]- back splice (also called an end splice) - A splice where the strands of the end of the rope are spliced directly back into the end without forming a loop. It is used to finish off the end of the rope to keep it from fraying. The end of the rope with the splice is about twice the thickness of the rest of the rope. With nylon and other plastic materials, the back splice is often no longer used; the rope strands are simply fused together with heat to prevent fraying.

- cut splice (originally called cunt splice) - A splice similar to the eye splice. It is typically used for light lines (e.g., the log-line) where a single splice would tend to come undone, the rope being frequently wet. It makes a very strong knot. A cut splice is a join between two ropes, made by splicing the ends slightly apart, to make an eye in the joined rope which lies shut when the rope is taut.

- eye splice - A splice where the working end is spliced into the working part forming a loop.

- horseshoe splice

- long splice - A splice used to join two rope ends forming one rope the length of the total of the two ropes. The long splice, unlike most splice types, results in a splice that is only very slightly thicker than the rope without the splice, but sacrifices some of the strength of the short splice. It does this by replacing two of the strands of each rope end with those from the other, and cutting off some of the extra strands that result. The long splice allows the spliced rope to still fit through the same pulleys, which is necessary in some applications.

- short splice - Also a splice used to join the ends of two ropes, but the short splice is more similar to the technique used in other splices and results in the spliced part being about twice as thick as the non spliced part, and has greater strength than the long splice. The short splice retains more of the rope strength than any knots that join rope ends.

- side splice

Tapering is also sometimes done to make the thicker splice blend or taper into the rest of the rope. It is does either by cutting off a lengthwise part of the end of each strand to make the end of the spliced part thinner or by staggering the strands so that the 2nd strand is interweaved one more time than the first and the third is interweaved an additional time after the 2nd. The staggering brings the splice from twice as thick as the rest of the rope to nearly the same thickness.

A fid is a tool (basically a hollow spike) that can be fit over the end of a strand and used to feed it through each loop as needed. It may be required for very tightly wound or large ropes.

A marlin spike is a tool, commonly part of a sailor's pocketknife, used to separate strands of rope from one another. It is basically a 3"-4" steel spike, slightly curved, with a non-sharp point that tapers quickly out to a 1/4" to 3/8" shaft in the space of the first 1" length.

External links

[edit | edit source]- Eye Splice Animation Using Rope - with Discussion

- New England Ropes Splicing Guide

- Short splice animation

- Eye splice animation

- William Falconer's Dictionary of the Marine

- Steel: The Elements and Rigging and Seamanship (1794) from The Maritime History Virtual Archives

- A. Hyatt Verrill Knots, Splices and Rope Work fromProject Gutenberg

- Guide to Wire-Rope Splicing - Mirror1 - Mirror2

- Photos of marlinspikes and fids

Stopper knots

[edit | edit source]A stopper knot is a knot that is tied in a rope to stop the end from going through a hole.

Stopper knots

[edit | edit source]Trick knots

[edit | edit source]Knots that are used as part of a magic trick, joke or puzzle.

Whipping

[edit | edit source]

A whipping knot or whipping is a binding of Twine around the end of a rope to prevent the fibres of the rope from unravelling.

When a rope is cut, there is a natural tendency for the cut end to fray. A whipping is one way to try to prevent this, by applying multiple turns of twine (sometimes called "small stuff") tightly around the rope very near the cut end. The whipping can be made neat and permanent by tying it off or sewing the ends of the twine through the rope.

When doing this to thick sailing-ship-type rope, the "small stuff" used was sometimes whipcord, hence the word usage.

Whipping is suitable for synthetic and natural ropes and lines. It is suitable for both stranded and braided ropes, lines and cables (3-strand rope, 4-strand cable and 8-strand multiplait as well as concentric and braided constructions).

Whipping takes time and some skill to apply, and may need specialist equipment (palm, needle etc). It provides a neat, soft, aesthetic, and permanent ending to the rope.

Types of whipping knots

[edit | edit source]

Alternatives to whipping

[edit | edit source]Constrictor knot

[edit | edit source]A Constrictor knot or a turn of self-adhesive plastic tape can be used temporarily to hold the fibres of a cut line until a final whipping can be applied.

Melting

[edit | edit source]The ends of some Synthetic fibres such as Dacron, Nylon, polyethylene, polyester, or polypropylene may be melted to fuse the fibers together and prevent their ends from fraying. This may be done by cutting through the rope with an electrically heated rope cutter, or cutting with a knife and melting the ends in a flame.

Although quick to apply and taking no great skill to learn, melting has a number of disadvantages. Many believe that melting the ends is most appropriate for finishing small-stuff, but is not recommended for working ropes and lines. Melting the fibers is a relatively poor method of finishing a rope's end, and the end of any rope subject to heavy use should be whipped as well. Melting cannot be done on wet rope and is often untidy when done on used or dirty rope. The melted end will be hard and can cause injury for example if flicked in the face. With age, use and ultraviolet damage, the hard end will crack and the sharp edges so produced can cut the hands in use, especially if the end runs through the palms. The melting process can easily be overheated causing an unsightly, rough, blackened end, especially if a hot flame is used. Melting is difficult to do outdoors in any breeze and, if the rope is overheated or catches fire, can produce toxic fumes in an enclosed space. There is a fire or injury risk on a boat, especially if the fibres catch fire and molten or burning plastic begins to drip.

Melting cannot be used on natural fibre ropes and lines, or on some types of synthetic lines. Natural fibres like manila, sisal, cotton and hemp will burn instead of melt. Aramid fiber such as Kevlar cannot be melted - the fibers merely char. Such rope must be finished with an appropriate whipping - ideally one completed with a needle such as a /Sailmaker's whipping although a /West country whipping also serves well.

Back splice

[edit | edit source]Whipping is not to be confused with Splicing, which uses the rope's own fibres. Splicing can be used to end a rope, to join two ropes together, or to join one rope to itself to form an eye or loop.

A Splicing/Back splice can be applied to the end of any rope, especially stranded ropes. It is most suitable for bucket ropes and other lanyards.

A back splice adds extra thickness to the end of the rope, so that it will no longer pull through blocks and sheaves. The extra thickness may however be seen as an advantage as it allows the user to feel the end of the rope coming into the hand, for example on a bucket lanyard when fetching water from a river bank or from the deck of a boat.

To be truly robust and permanent, the ends of the strands may still need whipping, or the whole splice serving after the back-splice is finished as this work will not be held in permanent tension, and may tend to unravel if banged around in use.

Splicing takes time and skill to apply, and may need special equipment (fid and small-stuff or self-adhesive tape) while working.

Liquid whipping

[edit | edit source]Another modern alternative is "liquid whipping". This is a commercial, glue-like product that is used by dipping the end of the rope into the liquid. When it sets, the product is flexible but solid enough to keep the rope together. Liquid whipping can be used on both natural and synthetic fibers.

Aglet

[edit | edit source]An aglet is a permanent ending applied mechanically to bind the end of the rope. A typical example is the plastic aglet at the end of a shoelace. Metal aglets may be crimped onto ropes or cables. Aglets may also be made by melting a softer metal to cap the end of the cable.