Papermaking/Fibres for paper

|

Different types of fibres can be used for producing paper. The most well-known is the wood fibre. In the beginning of papermaking mostly fibres from cotton and silk were used. A notorious fibre that at one time was used for producing a specific papergrade was asbestos. Until the late sixties of the 20th century this cancer causing fibre was used to produce asbestos paper. This lead to elevated cancer death rates specially within the group of papermakers, who produced this type of paper. Different types of plants can and are used for producing paper, like bamboo from China. Phragmites can also be used as raw material for paper, still in the nineties of the 20th century producing paper from phragmites was investigated in Holland.

Wood pulp[edit | edit source]Pulp from wood is the most important raw material for paper. Another, less correct name, which is used for pulp is cellulose. Wood pulp as raw material is formed after the following treatments:

This last part of the process is only necessary when the production of paper is not integrated with the production of wood pulp. The last step is necessary when the paper mill is located on a different location than the raw material source. Hardwood and softwood can both be used to for paper. Usually wood pulp from eucalypt trees is treated as a separate group although it is in fact hardwood, because it has special dimensions (relatively short, but thick), which gives it unique properties. In some countries paper industry exist without the existence of pulp mills in this country, like Holland. All wood pulp for the production of fine paper is imported. Typical hardwood used in the paper industry comes from:

Typical softwood:

Fibres from tropical hardwood trees are not as suitable for production of paper. This is contrary to what people think.

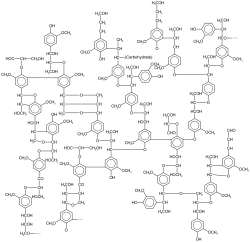

Defibring of wood pulp[edit | edit source]For this chapter some knowledge about chemistry is required There are two main types for defibring: mechanical or chemical. There exist however also a intermediate. Mechanically defibred pulp is called "wood containing", whereas chemically defibred pulp is called "woodfree". Wood containing is misleading, because it only says if lignin is present in substantial amounts. Pulp, as is, is usually only used for chemically defibred fibres, but the mechanical defibring is also mentioned here.

Mechanical pulping process[edit | edit source]The first method we consider is stone groundwood. The stem of a tree is pushed onto a turning ground stone. This process leads to a lot of heat formation, which is why the wood needs cooling. The high temperature attenuates the lignin (which is the binding component between the fibres), which is why the individual fibre is freed. Part of the fibres is not only freed but is also shortened.

The second defibring method is pressure groundwood. The third defibring method is thermo groundwood. The fourth defibring method is RMP, refiner mechanical pulp. The fifth defibring method is CRMP, chemical refiner mechanical pulp. The sixth defibring method is TMP, thermo mechanical pulp. The seventh defibring method is is CTMP, chemo thermo mechanical pulp. This last method is also called "semi-chemical" and is the transistion from mechanical to chemical pulp.

Chemical pulping process[edit | edit source]

|

Summary

Quote

|

Resources

[edit | edit source]Consistency Measurement - Pulp consistency measurement and control for paper industry.