Plastics Molding & Manufacturing/Plastic Process

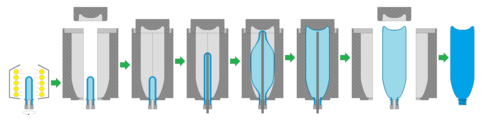

Blow Moulding

[edit | edit source]

Suitable for moulding parts with hollow inner sides such as bottles.

A plastic tube is heated up preparing to be inflated by gush of hot air. Later, the hot air pushes and expand the plastic against the mould to form the desired mould shapes. Once the plastics is cooled, the plastic is ejected from mould.

The animation shows the process of blow moulding

Compression Moulding

[edit | edit source]

Suitable for moulding parts with high strength compounds such as fiberglass and reinforced plastics for automobiles parts

Heated plastic resins is poured into the heated mould. The plastic resins is compressed into the cavity of mould shapes by the other half mould. The material is left to be cured inside the mould to maintain material strength and integrity. The other half of mould is slowly removed from the cavity and plastic is left to be cooled. Once the plastics is cooled, it is removed from mould. Any of the flashing formed during compression are removed.

The video shows compression moulding of terminal block

Extrusion Moulding

[edit | edit source]

This process is suitable for long hollowed products such as pipes, tube, straws, cables and etc

The mechanism for extrusion moulding is similar to the injection moulding but instead of pushing into a mould, the heated plastics resins is get pushed thru a die shape which determine the shape of the final products. The plastics is usually cooled thru the winding cooling chambers (or water tanks) and will be cut in a determined length and packaged in bundles.

The video shows the extrusion moulding of PVC pipes

Injection Moulding

[edit | edit source]

Suitable for high volume of mass production with consistent quality such as plastic products found in supermarket

The plastic resins is pushed under high temperature and high pressure into the cavity of the mould thru the runner. The viscous resins are filling the cavity which will form the shapes of the products. The mould clamp forces are high enough to prevent the spillage of the resins injection forces which is known as flashes. The plastic products are kept cooled for a few seconds and the mould are then opened slowly to let the air to break the vaccuum formed inside the injection mould. The plastic products are ejected from the mould using the ejector pins. The leftover products such as gatings/sprue are often grinded to be reused as recycled plastics.

The video shows the injection moulding of a chair.

Rotational Moulding

[edit | edit source]

Suitable for large, hollow and one piece components such as large tanks

The plastics are heated constantly at high temperature and are rotate around inside the mould. The constant rotations allowed the plastic to be applied uniformly inside the mould wall. It is very suited to moulded large parts such as liquid tank. Very little material is wasted due to there are no gating required.

The animation below shows rotational moulding of large water tanks

Multi material injection molding

[edit | edit source]

Suitable for parts that requires two or more different type of materials to be molded . In industry, it is also known as 2k mould.(For example shown: Toothbrush molded with two or more different materials)

In summary,

| Process | Part's Complexity | Components | Forming Action | |

|---|---|---|---|---|

| Blow Moulding | Complex Hollow | Drinking bottles | Inflation | |

| Compression Moulding | Simple | Thermoset Appliances Casing | Compression | |

| Extrusion | Simple | Tubes, pipes | Extrusion | |

| Injection Moulding | Complex | Household items | Injection | |

| Rotational Moulding | Simple | Giant Tank | None |