Sustainable Business/Manufacturing

ABOUT THIS BOOK | THE BUSINESS PLAN | BOOKLETS | PRINT THIS BOOK

This section deals with how goods are to be produced. If you do not manufacture anything (for example, if you operate a pure service business) then you can skip this section. It is therefore concerned with organising and controlling the production function. The aim is to ensure that goods are made in the right quantities, at the right quality, at the right time and at the right cost.

The operations section helps you to answer the following questions:

- What sort of product will you produce?

- What plant or machinery do you require?

- Where will you locate your business?

- How will you organise the production sequence of the product to maximise profitability?

- How will your staff impact on design and production?

- What stocks of raw materials are needed?

- How can you use resources more efficiently?

- How do you make sure that you are in control?

As you work through these questions you will realise that they are interrelated and that the answer to one question impacts on all the others. The questions concern the operations section that, more than any other area, has the potential to dictate the profitability of the business.

Operations is about throughput. This involves the transformation of inputs such as raw materials into outputs, that is, sales. Remember that business is about generating sales. Producing inventory doesn’t make a successful business; producing, selling and getting paid does.

The product

[edit | edit source]From your marketing research you should know the type of product you want to sell.

- What are the product’s specifications?

Outline in detail what it is that you aim to produce or sell. This will help when it comes to buying equipment or if you wish to subcontract a part of the production process.

For example: Carbonated liquids must be bottled in the right type of bottle with the right cap so as not to lose fizz.

- Product design

There are many opportunities for manufacturing efficiency that are intrinsic to your product’s design. What you decide at the design stage can either limit or open up opportunities for manufacturing efficiency and end-of-life disposal. Examples include:

- Minimising the amount of material resources used in the product while retaining functionality (‘dematerialisation’).

- Designing a quality, durable product.

- Maximising the proportion of recyclable materials in the product. For example, this may mean avoiding composite materials where possible.

- Minimising the use of hazardous substances. There are in many cases acceptable non-hazardous alternatives that fulfil the same function.

- Designing recyclable product packaging.

For more information, search the internet for Design for the Environment (DfE).

- Should you make everything yourself?

It does not always make sense to try and manufacture the whole product yourself.

It often makes more sense to subcontract a part of the manufacturing process or buy in ready-made parts.

For example Imagine you are a soft-drink manufacturer. Should you subcontract the printing of the labels or should you purchase your own printing press to print the labels? In this example the answer is obvious (subcontract the printing). However, this is not always the case.

To help decide which part of the process to subcontract, ask yourself these questions:

- Should you subcontract?

- Can the subcontractor manufacture to a competitive price and to your specifications?

- Is the subcontractor able to deliver at the times you require?

- Does the subcontractor have competitors who could carry out

the contract if required?

- This part of the process is not strategically important to your business (answer Yes if this statement is true).

- This part of the process is not your core competitive advantage (answer Yes if this statement is true).

For example, in the case of the soft-drink manufacturer it may be feasible to subcontract the bottling process because the distribution and marketing of soft drinks is the company’s core competency.

If you answered yes to all the above questions then subcontracting may be a real option. If you only answered yes to one of the questions you should probably manufacture it yourself.

The plant

[edit | edit source]This is important for all businesses. The design stage is your first and best opportunity to ensure that unnecessary product, materials and energy waste is minimised.

In the case of a restaurant, for instance, the design might detail the flow of how people will enter, where they will sit, what form of lighting is most efficient and should include the mapping of how meals will be assembled.

Obviously the type of business you plan will dictate the type of plant you require. A retail store will need items such as display racks and mirrors as well as cash registers. An office-based business will require chairs, desks, computers and printers. A manufacturing concern will require processing equipment and so on.

There are specific stages to this part of the section.

- a) Designing the process

This is important for all businesses. In the case of a restaurant, for instance, the design might detail the flow of how people will enter, where they will sit and should include the mapping of how meals will be assembled.

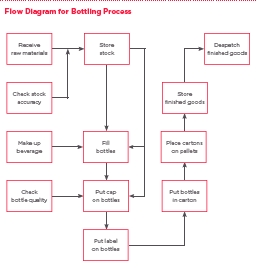

In the case of a bottling plant, the layout will need to take account of the most efficient flow of materials and operational processes.

For example

Remember also to consider the broader issues of health and safety in your work environment when you’re considering your processes. It is a good idea to contact the Occupational Safety and Health (OS H) service of the Department of Labour for further health and safety details and guidance (see www.osh.dol.govt.nz for details of your nearest OS H Information Support Officer). Then incorporate their requirements and recommendations into your plan.

- b) Machinery required

Now detail at each stage of the process what plant and machinery is required. Write the specifications and the approximate cost of each item. Try to be as specific as possible and do not overlook any necessary piece of equipment, including health and safety equipment such as dust extractors, guards on machines and safety signage. Consider also the ongoing maintenance and running costs of machinery. For example, energy efficient machines will have a lower running cost.

- c) Capacity of each stage

It is important to identify the capacity of each stage of the process. Note that you can only produce as fast as the slowest part of the process.

In the above flow diagram, the capping machine is the slowest machine in the process. If this machine operates at 1,000 bottles per hour, then this figure effectively sets the overall rate of production for the whole process.

- d) Establish the area required

Now it should be possible for you to gain an indication of how much space you will need. A simple way to do this is to make a scale drawing of how much area each piece of plant and machinery requires. Then arrange the drawings into the sequence that you decided upon in the flow diagram. This should give you an idea of the overall production area you require.

Remember to allow space to receive shipments, store stock, greet customers, display goods, manufacture products, do office work, and so on.

For example:

- e) Special requirements and licenses

If you plan to produce a food product you will require premises capable of being licensed for food production. Your plant and machinery might also have to meet special requirements such as stainless steel fittings.

It is important that you contact your local council to ensure that you will be able to meet all the legal requirements to operate and obtain the necessary licences. Alternatively, if you are already in business, you should check that you are complying with all legal requirements.

Locating the business

[edit | edit source]The choice of location may very well be one of the factors most critical to the success of your business.

The factors that help determine your location are complex and require a great deal of thought.

Your market research should play an important part in determining the location. Then again, because most commercial properties have leases that are fixed at multiples of a year, you need to be sure you have chosen correctly because you might be stuck there for a considerable period of time.

Here are some of the questions you need to work through:

- 1. Cost of location?

The cost of rental is an important factor. Having already decided on how much space you require, you can now work out the cost of that space in different locations. For example, choice of location is critical if you are a retailer as well as a manufacturer. You would need to confront issues such as:

- do you need extra parking for your customers, and

- do you locate in a mall or outside a mall?

- 2. Where are the customers?

Do you locate as near as possible to your customer base or should you locate somewhere else? Should you freight your product to your customers or require them to travel to you?

Will they be prepared to do this?

- 3. Availability and cost of labour?

If you require skilled labour to help operate your business is this labour available in the area you plan to locate in or can they easily travel to you?

- 4. Availability of raw materials?

For most manufacturers raw material can easily be transported within New Zealand. It is the cost of transport that has to be considered. If your raw materials cannot sustain a high freight cost then it is probably best for you to locate as close as possible to the raw material supply.

This is especially important if your raw material is perishable. You may also need to think of the longer term availability and cost of raw materials. For example, petroleum based plastic resins will increase with the oil price.

- 5. Availability of transport?

If your business were export focused or geared towards the overseas tourist market then it would make sense for you to be close to a port or international airport.

Organising the sequence

[edit | edit source]How will you organise the production sequence to maximise profitability? A manufacturing facility can be designed to produce one product or it can be designed to produce a range of products.

| One product | Multiple products |

| Large production runs | Small batch production |

| Focused production process | Flexible production facilities |

| Low number of inventory items | Large number of inventory items |

There are advantages and disadvantages to both strategies. For example, if you are considering exporting, you may need large capacity. Many business people have developed export markets only to discover they cannot produce the orders requested.

Therefore, if you are considering exporting, you may have to dedicate the facility to produce reasonable volumes of a few products. The danger in this strategy is that if the market changes, your facility may lack the flexibility to produce other products.

How staff impact on design

[edit | edit source]We have seen that the availability of staff is a factor in influencing your choice of location.

You should also take staff into consideration when you design your process. Automating production processes is a method of reducing staff requirements, but this usually requires large amounts of capital.

When you design a manufacturing facility you should take into account the human needs of your staff. The facility should be spacious, well-lit and ventilated, feature good climate control and be free from fumes and excessive noise.

As mentioned before, you will need to meet specific health and safety requirements. However the design of the process should go beyond the minimum legal requirements to consider the ease of operation, that is, the relationship between the operator and the machine. Try imagining yourself doing the job, eight hours a day, five days a week, all year and for the pay you are prepared to offer. Would you be productive in the circumstances you have designed?

What stocks of raw materials are needed?

[edit | edit source]You should research potential suppliers well in advance of start up. Since New Zealand is a long way from the rest of the world, you should establish how long it would take for stock and inventory sourced overseas to arrive. If you are sourcing materials that might take months to arrive, you will have to hold enough raw materials on hand to ensure that you do not run out of stock. This can turn out to be an expensive exercise.

Even though local suppliers might be more expensive, they could save you the cost of investing in large inventories.

Large inventories soak up a lot of money. What some manufacturers do is maintain a minimum stock level and receive deliveries more frequently. This is called ‘just-in-time’ inventory management.

Resource efficiency

[edit | edit source]It is becoming more important to show your customers that you run an environmentally responsible business. So everything you can do to reduce waste and environmental damage will add to your credibility in the marketplace.

Also, resources cost you money to purchase so the more efficiently you can use them the lower your costs and the more efficiently your operational systems function. For instance, $10 saved in costs can be the equivalent of $100 earned in sales. The simple equation is: Materials Waste = Unnecessary Cost.

Some key resources where you can make savings are:

- Energy

Through simple actions businesses can easily save 10 percent of their energy costs.

Visit www.emprove.org.nz for more ideas and information.

- Water

There are simple things you can do to ensure you are not losing water or using too much. When purchasing machinery check the energy efficiency rating and other efficiency considerations such as use of water. More efficient machinery reduces your on-going running costs.

- Packaging

Minimising the amount of packaging you use on your products often brings additional benefits.

For example, you can reduce the original packaging cost and fit more product into a transport container. Other steps you can take include:

- increasing the recycling content in packaging

- ensuring that packaging can be recycled by the customer

- minimising the amount of packaging you get from a supplier.

If possible, try to get reusable containers from your suppliers as this saves you the cost of disposing of their packaging.

- Transportation

Significant cost savings can be achieved through careful travel planning to minimise distance and time spent travelling. Choosing energy efficient vehicles will also assist savings.

- Waste

Waste is an often unrecognised cost to your business, so use the waste hierarchy shown below throughout all your operations to reduce waste.

As the hierarchy shows, prevention in the first place has the most effect, followed by reduction, reuse and recycling. Putting in place the first four steps significantly reduces the need for the final step, responsible disposal:

For any waste produced, ask how can you:

- Eliminate the waste entirely?

- Reduce the amount of waste?

- Re-use or rework the waste?

- Recycle the waste?

- Responsibly dispose of the waste?

- Develop performance indicators (for resource efficiency)

Resource efficiency can both save significant costs and enhance your brand, but appropriate measurement is a pre-requisite to effective identification of savings opportunities and their subsequent maintenance. Financial indicators alone are not enough to monitor a sustainable business.

Take the time to develop manufacturing and process related indicators that cover environmental and social aspects of your business, as well as cost related indicators. Market perception and demands are increasingly looking for indicators of both environmental and social responsibility, and you need to manage all key factors within your control that affect your business. Setting targets and tracking progress for a selection of key performance indicators will help improve your competitiveness. (See Chapter 11 for some suggested KPIs)

How will the whole process be controlled?

[edit | edit source]Quality control is a critical success factor. Quality can be defined as meeting the customer’s stated, unstated and future needs. To meet these needs and to maintain a consistent quality of production you need to identify what the critical quality issues are and design tests that can be used to ensure that quality is being maintained.

For example: A problem that can exist in bottling plants is that a variable amount of liquid is placed in the bottles. Therefore a system has be designed to ensure that samples of bottles are taken at regular intervals and measured to establish if the right quantity of fluid is being placed in each bottle.

Putting quality checks in place is very important if you are to ensure that customers receive a standard quality product. If something does go wrong, you need to fix the process itself so that it does not happen again.

There are various quality assurance programmes available to you. Check, though, that the cost of a particular programme does not outweigh the benefits. Contact your local manufacturers’ association (www.ema.co.nz) for assistance in this area. You could also contact a quality consultant, but take care in choosing the most appropriate consultant for your needs.

The impact of e-commerce

[edit | edit source]Remember the impact of e-commerce on your operations. For example, have you considered the following:

- Linking your production, inventory and sales systems to improve efficiencies such as lowering the amount of raw materials you hold?

- Sourcing staff via employment websites as an alternative to conventional staff sourcing?

In addition:

- Trade hubs and electronic markets may be able to put you in touch with suppliers that you have never previously considered

- You may be able to contract out parts of your production via the internet

- Some customers may demand that you integrate electronically with their production systems

- Some customers will not buy off you unless you can pay and generate an invoice electronically.

All of these issues will become more and more important in your business as e-commerce becomes another way of doing business (until eventually the ‘e’ will be dropped as these procedures simply become standard business practice).

Summary

[edit | edit source]Manufacturing management is an important part of your business planning. If you are in business, inventory control and production planning are critical to ensure that you can meet customer demand, but do not over-invest in raw materials and inventory.

Developing and regularly monitoring a key set of performance indicators is critical to maintaining your manufacturing efficiency and your competitiveness. These indicators need to be resource as well as cost based, and should be related to your unit production (e.g. per widget).

Production planning needs to be carried out to ensure that your products are produced, and customers serviced, in the most efficient manner. If you have an existing plant or process, never assume that it is running at maximum efficiency. Periodically re-examining everything you do is a sound way of identifying what could be done to improve the efficiency of your business.